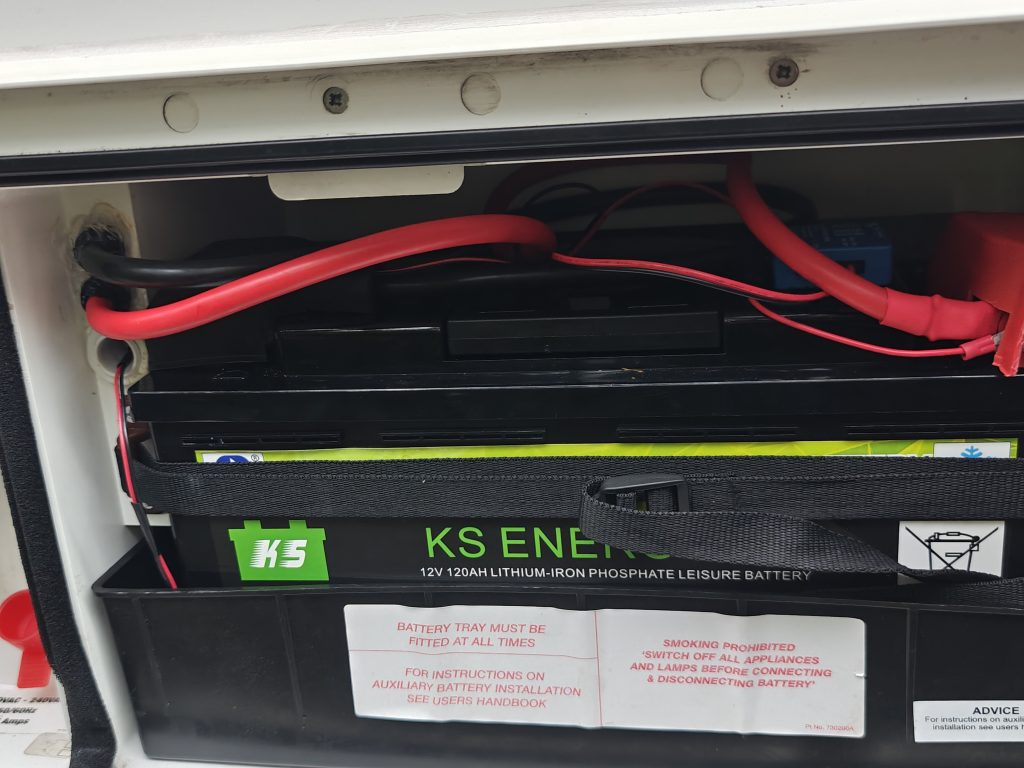

A quick look in our battery box revealed a tangled mess of wires and always a challenge to remove the battery from the compartment. And only two different connections – 12v to the Sargent control unit and 12v to the motor mover. The motor mover cables were too long and haphazardly tied together with insulation tape.

All I really needed to achieve was to add a voltage sensor across the Lithium battery, to accurately measure voltages and thus ensure the Victron MPPT controller can work to its best.

I also wanted the flexibility to future add some extra solar panels (portable) and again these really needed to connect close to the battery. I also wanted to run a 1500w inverter.

My solution was…

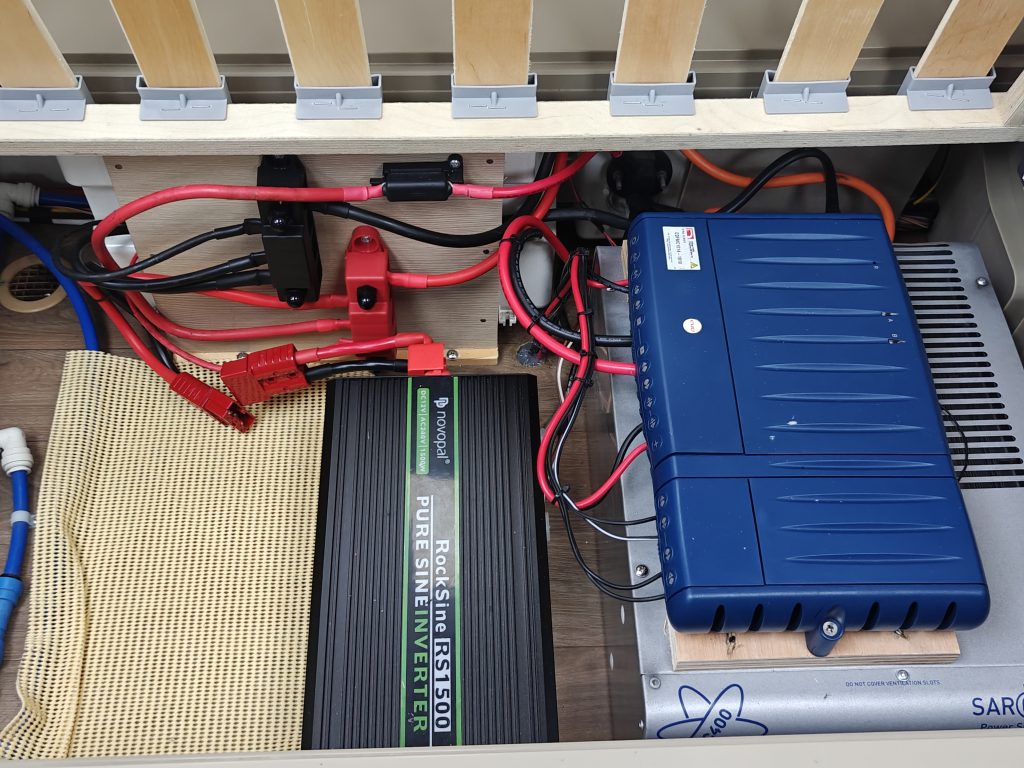

Relocate the Motormover controller to sit on top of the Sargent control unit, keeping the cooling grills free of obstruction. This would create extra floor space for the Inverter and 12v distribution board. The board was some unused lightweight caravan cupboard shelving and I attached 4-way 12v Busbars from Amazon. Most of the other components came from 12v Planet.

I would then feed just two 25mm2 cables from the distribution board to the battery. These are ultra flexible and capable of carrying in excess of 170A. I added a 170A Cube fuse to the battery’s positive terminal.

Whilst not strictly without risk, I also shortened the motor mover battery to controller cable.

The inverter then sits next to the Sargent unit and is mounted with thumbscrews and a huge Anderson connector to allow it to be removed. It’s quite heavy so I wanted the option to be able to take it our easily.

The Victron sense connects to the battery terminals and sticks to the top of the battery. It monitors the temperature and voltage at the battery and feeds this over bluetooth to the Victron controller, negating any voltage losses which occur in the conservatively-sized Swift wiring.

Here’s a picture of the battery box:

And the 12v Layout under the front bench seat.